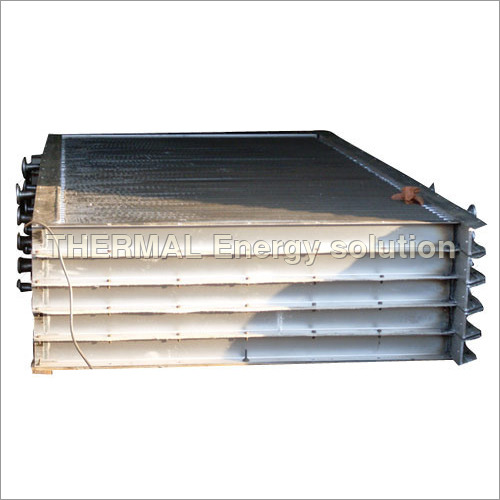

Rice dryer Heat Exchange

3500.0 INR/துண்டு

தயாரிப்பு விவரங்கள்:

- தட்பவெப்பநிலை

- கண்டிஷன்

- பயன்பாடு Industrial

- கட்டமைப்பு

- அளவு Standard

- தயாரிப்பு வகை Rice dryer Heat Exchange

- கலர் Silver

- Click to view more

X

விலை மற்றும் அளவு

- 1

தயாரிப்பு விவரக்குறிப்புகள்

- Industrial

- Standard

- Silver

- Rice dryer Heat Exchange

வர்த்தகத் தகவல்கள்

- மாதத்திற்கு

- நாட்கள்

தயாரிப்பு விவரங்கள்

A rice dryer heat exchanger Manufacture in chennai, tamilnadu and india

a key component in modern rice milling systems that uses a heating medium, such as steam, hot water, or hot combustion gases, to produce clean hot air for drying paddy. This indirect heating process prevents the rice from being exposed to harmful pollutants from the heat source, resulting in higher grain quality and safer processing

Efficient Heat Exchange Technology

The plate heat exchanger design allows these units to maximize heat transfer between mediums, enhancing the drying speed for rice processors. This efficiency minimizes energy consumption and supports consistent grain quality, even at medium temperature levels.

Versatile Sizing and Advanced Construction

Available in multiple sizes, these heat exchangers cater to varied operational needs for rice mills. Constructed with premium materials and a robust silver finish, they promise both durability and low maintenance, suitable for continuous, industrial-scale use.

FAQs of Rice dryer Heat Exchange:

Q: How does the plate heat exchanger improve rice drying efficiency?

A: The plate heat exchanger maximizes the contact surface for heat transfer, enabling rapid and uniform temperature distribution throughout the rice dryer. This results in reduced drying times, improved energy efficiency, and preservation of grain quality.Q: What sizes are available for the rice dryer heat exchanger?

A: We offer various sizes to accommodate different processing capacities, ensuring an effective solution for both small and large rice milling operations. Please contact us with your specific requirements for guidance on the most suitable size.Q: When should a rice mill consider upgrading to a medium-temperature plate heat exchanger?

A: An upgrade is recommended when aiming to boost operational efficiency, minimize energy costs, or replace outdated systems. If you notice uneven drying or increased energy usage, upgrading to a modern plate heat exchanger provides notable benefits.Q: Where are your rice dryer heat exchangers manufactured and supplied from?

A: All of our rice dryer heat exchangers are manufactured, exported, and supplied from India, adhering to international quality standards and serving clients worldwide.Q: What is the process for installing a new rice dryer heat exchanger?

A: Installation is systematic and begins with selecting the correct size and model. Our technical team assists with setup, ensuring seamless integration with your existing rice drying system and providing support for operation and maintenance thereafter.Q: How can these heat exchangers be used in rice processing plants?

A: They are integrated into rice drying systems, serving to transfer heat efficiently during the drying phase. This helps optimize moisture removal, ensuring quality and consistency in the end product.Q: What are the main benefits of using your rice dryer heat exchanger?

A: Key benefits include enhanced energy efficiency, consistent grain drying, reduced operational costs, and long-lasting performance. The robust plate structure ensures durability, making it a smart investment for rice processors seeking reliable technology.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

கைபேசி number

Email

வெப்ப பரிமாற்றி உள்ள பிற தயாரிப்புகள்

|

THERMAL ENERGY SOLUTIONS

அனைத்து உரிமைகளும் பாதுகாக்கப்பட்டவை.(பயன்பாட்டு விதிமுறைகளை) இன்ஃபோகாம் நெட்வொர்க் பிரைவேட் லிமிடெட் . உருவாக்கப்பட்டது மற்றும் நிர்வகிக்கப்படுகிறது |