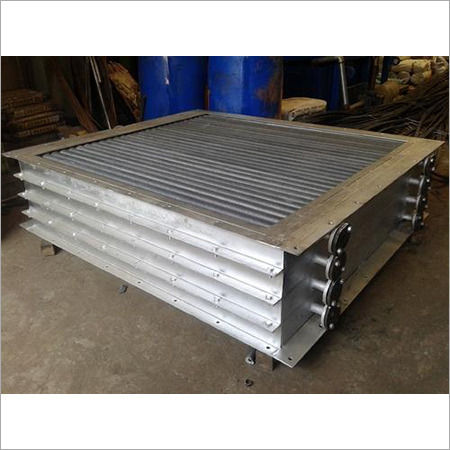

Steam Heat Exchangers for Rice Mill

Product Details:

- Usage Industrial

- Condition New

- Structure tube Heat Exchanger

- Size Different Sizes Available

- Product Type Heat Exchanger

- Color silver

- Click to view more

Steam Heat Exchangers for Rice Mill Price And Quantity

- 25000 INR/Unit

- 1 Unit

Steam Heat Exchangers for Rice Mill Product Specifications

- Heat Exchanger

- New

- Industrial

- silver

- tube Heat Exchanger

- Different Sizes Available

Steam Heat Exchangers for Rice Mill Trade Information

- 1 Unit Per Week

- 1 Days

Product Description

Steam Heat Exchangers for Rice Mill are properly crafted with tubes, shell sides, and turbines at our highly advanced setup, making it ideal for transporting heat energy. In addition, we provide a broad selection of heat exchangers with competitively priced options in a variety of capacities. Our provided product has sleek style and are highly efficient thermally. To avoid hydrate formation, lower viscosity, and break down emulsions for effective oil and water separation, well effluents are heated using maintenance-free exchangers.

Steam Heat Exchangers for Rice MillSpecifications:

|

Minimum Order Quantity |

1 Piece |

|

Brand |

TES |

|

Application |

Hydraulic and Industrial Process, Power Generation |

|

Type |

Air-Cooled |

|

Medium Used |

Water, Air |

|

Finishing |

Galvanized |

Advanced Thermal Engineering for Rice Processing

Designed specifically for rice mill applications, these steam heat exchangers offer optimized heat transfer. The tube-style construction ensures reliable, even heating throughout the process, minimizing energy loss and improving yield. Each unit is manufactured under strict quality standards to guarantee longevity and consistent performance in demanding industrial environments.

Customizable Solutions for Diverse Needs

Recognizing the varied requirements of rice mills, our heat exchangers come in different sizes to suit both large-scale and smaller operations. Expertly crafted in India, these exchangers can be tailored to fit seamlessly into your existing systems, delivering both versatility and operational efficiency.

FAQs of Steam Heat Exchangers for Rice Mill:

Q: How does a steam heat exchanger benefit rice mills?

A: A steam heat exchanger optimizes heat transfer during rice processing, ensuring efficient steam utilization and consistent temperature control. This results in improved grain quality, reduced energy consumption, and lower operational costs for rice mills.Q: What is the process for integrating these heat exchangers into an existing rice mill system?

A: Our steam heat exchangers are engineered for straightforward integration. After an assessment of your facilitys steam needs and space, the appropriately sized exchanger is installed by professionals, ensuring minimal disruption and maximum compatibility with your current setup.Q: When is it advisable to replace or upgrade a steam heat exchanger in a rice mill?

A: It is recommended to consider replacement if your current exchanger is experiencing frequent breakdowns, reduced efficiency, or visible corrosion. Upgrading ensures improved energy efficiency, reliability, and compliance with modern industrial standards.Q: Where are these steam heat exchangers manufactured and supplied from?

A: We manufacture and supply our steam heat exchangers from India, and serve clients as an exporter, manufacturer, and supplier to various international markets as well as local rice mills.Q: What types of sizes are available for your steam heat exchangers?

A: Our product line features steam heat exchangers in various sizes, allowing customization to match the capacity and operational demands of different rice mills, whether small-scale or industrial-grade facilities.Q: How should these exchangers be maintained for optimal performance?

A: Routine maintenance involves periodic cleaning of tubes, inspection for leaks or deposits, and ensuring proper steam flow. Adhering to recommended service intervals helps extend the lifespan and efficiency of the unit.Q: What are the primary industrial uses for these steam heat exchangers besides rice milling?

A: While specifically designed for rice mills, these steam heat exchangers can also be deployed in other industrial applications requiring efficient thermal transfer, such as food processing, chemical plants, and manufacturing facilities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Steam Heat Exchangers' category

|

THERMAL ENERGY SOLUTIONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |