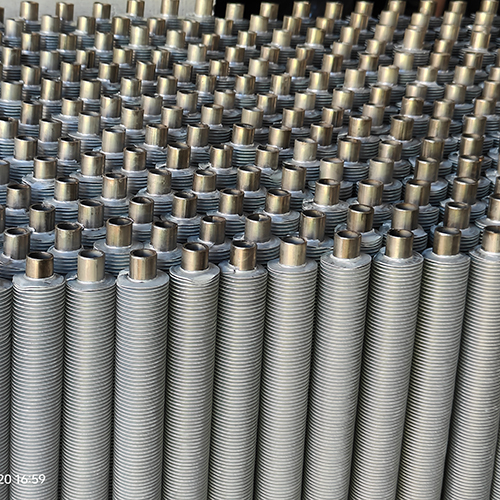

Integrally Fin Tubes

Product Details:

- Material Alluminium

- Shape Round

- Grade Industrial

- Size Different Sizes Available

- Color Black And Golden

- Warranty Yes

- Click to view more

Integrally Fin Tubes Price And Quantity

- 50 Meter

- 300.00 INR/Meter

Integrally Fin Tubes Product Specifications

- Yes

- Alluminium

- Industrial

- Different Sizes Available

- Black And Golden

- Round

Integrally Fin Tubes Trade Information

- 50 Meter Per Week

- 1 Days

Product Description

Integrally Fin Tubes are perfect for industries that seek to improve fluid heat transfer performance while reducing the physical size and expense of heat exchangers. Most materials that are tubular can be finned. The fin code or fin profile, however, is determined by the materials hardness. Apart from these, it often utilize air to cool or heat fluids like air, water, oil, or gas, or they can be used to recover or collect waste heat. Numerous sectors, including oil and gas, power production, maritime, and HVAC&R, can employ them.

Integrally Fin Tubes Specifications

|

Minimum Order Quantity |

333 Meter |

|

Finishing |

Galvanized |

|

Unit Length |

3m, 6m |

|

Type |

Integrally Finned Tubes, External Finned Tubes, KL Finned Tubes, L Finned Tubes, G Finned Tubes |

|

Size |

1/4 inch-1 inch |

|

Material |

Stainless Steel, Mild Steel, Carbon Steel, Aluminium |

Enhance Heat Transfer Efficiency

Our Integrally Fin Tubes are engineered to boost the performance of heat exchangers by increasing the surface area for heat transfer without expanding the overall tube size. Constructed from robust aluminum, these tubes handle rigorous conditions and deliver consistent, reliable results. Their round design helps achieve uniform heat distribution, making them ideal for industrial settings where energy efficiency is paramount.

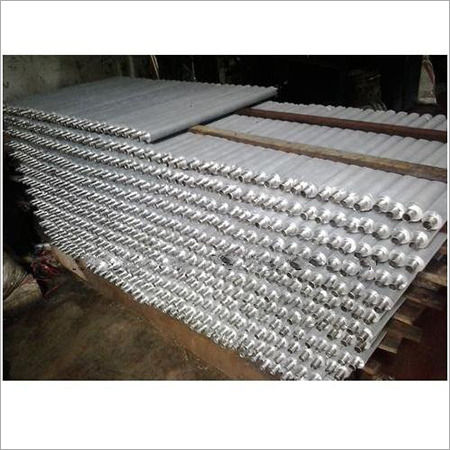

Customizable Solutions for Diverse Requirements

We offer Integrally Fin Tubes in a wide range of sizes to cater to various industrial applications. Whether for large-scale or specific plant needs, the tubes can be tailored in terms of length, fin density, and color (black or golden) to integrate seamlessly into existing systems. Our in-house manufacturing processes ensure quick turnaround times and the highest quality standards for our customers across India and around the globe.

FAQs of Integrally Fin Tubes:

Q: How are integrally fin tubes manufactured?

A: Integrally fin tubes are produced using a specialized process where fins are directly formed from the tube material (aluminum) by extrusion or rolling. This creates a strong bond between the fins and the base tube, ensuring durability and efficient heat transfer.Q: What are the primary uses of integrally fin tubes in industrial settings?

A: These tubes are primarily used in heat exchangers, condensers, and air coolers. Their enhanced surface area improves heat transfer efficiency, making them ideal for applications in power plants, chemical processing, refrigeration, and HVAC systems.Q: When should integrally fin tubes be chosen over plain tubes?

A: Integrally fin tubes are preferred when enhanced heat transfer is needed without a significant increase in equipment size. Their design is especially advantageous in compact systems or when operating under harsh environmental conditions.Q: Where can I source integrally fin tubes in different sizes and grades?

A: We are a trusted exporter, manufacturer, and supplier based in India, offering integrally fin tubes in a variety of sizes, shapes, and colors. Customized orders can be fulfilled to meet your specific industry requirements.Q: What benefits do integrally fin tubes made of aluminum provide?

A: Aluminum integrally fin tubes offer excellent thermal conductivity, lightweight construction, and corrosion resistance. This results in longer product life, reduced maintenance costs, and superior performance in heat transfer applications.Q: How does the warranty on integrally fin tubes work?

A: Each integrally fin tube comes with a manufacturers warranty, ensuring any defects in materials or workmanship are covered. Detailed terms can be provided upon request with your quotation or purchase order.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Finned Tubes' category

|

THERMAL ENERGY SOLUTIONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |