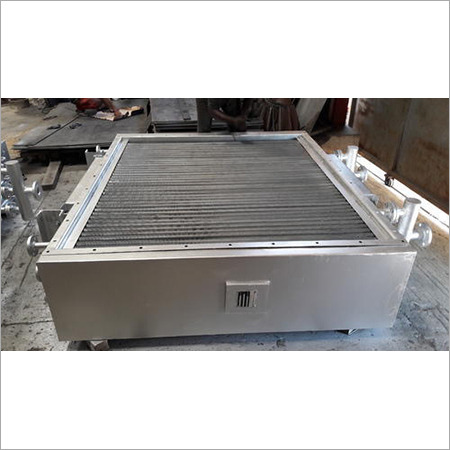

Heat Exchangers for Spray Dryers

Product Details:

- Usage Industrial

- Condition New

- Structure tube Heat Exchanger

- Size Different Sizes Available

- Color silver

- Click to view more

Heat Exchangers for Spray Dryers Price And Quantity

- 25000 INR/Unit

- 1 Unit

Heat Exchangers for Spray Dryers Product Specifications

- Industrial

- silver

- New

- Different Sizes Available

- tube Heat Exchanger

Heat Exchangers for Spray Dryers Trade Information

- 1 Unit Per Week

- 1 Days

Product Description

Heat Exchangers for Spray Driers may be utilised in spray drying processes for the manufacturing of goods like: food, dairy, chemicals, and pharmaceuticals for air management and heat recovery. They ensure that optimum productivity and homogeneity are achieved in drying applications. They are very effective and safe to use. It is used for baby milk powder, coffee grounds, powdered protein, starch, vitamins, and so on. The stainless steel structure is offered, offering reliable and enduring performance support.

Heat Exchangers for Spray Dryers Specifications

|

Minimum Order Quantity |

1 Piece |

|

Type |

Coil, Tube, Air-Cooled |

|

Medium Used |

Oil,Air |

|

Application |

Food Process Industry,Pharmaceutical industry, Hydraulic and Industrial Process |

|

Inlet Temperature |

25 degree centigrade |

|

Brand |

Thermal Energy Systems |

|

Outlet Temperature |

150 degree centigrade |

Engineered for Industrial Efficiency

These tube heat exchangers are optimized for high-performance industrial spray drying, delivering consistent and effective heat transfer. Built to support continuous operation, they are manufactured using advanced techniques and top-grade materials, ensuring durability and safety during demanding processes.

Versatile Sizing and Flexible Installation

Available in a range of sizes, our heat exchangers cater to varied plant requirements. This flexibility allows seamless integration into both new and existing spray dryer systems, maximizing operational compatibility and minimizing downtime during installation or upgrade.

FAQs of Heat Exchangers for Spray Dryers:

Q: How do tube heat exchangers function in spray dryer systems?

A: Tube heat exchangers work by transferring heat from a heating medium to the air or gas used in the spray drying chamber. This process ensures that the air reaches the desired temperature for effective drying of materials in industrial settings.Q: What are the benefits of using these heat exchangers in industrial spray dryers?

A: Utilizing our heat exchangers enhances energy efficiency, improves product quality, and reduces operational costs. Their robust design and superior thermal performance lead to consistent drying results and minimal maintenance requirements.Q: When should I consider upgrading or replacing a heat exchanger in my spray dryer?

A: Upgrade or replacement is recommended if your current heat exchanger shows signs of reduced efficiency, increased energy consumption, or frequent maintenance issues. Our new models offer improved longevity and better performance.Q: Where are these heat exchangers manufactured and supplied from?

A: All our heat exchangers are expertly manufactured, supplied, and exported from India, ensuring premium quality and compliance with international industrial standards.Q: What is the installation process for your heat exchangers?

A: The installation process is straightforward, supported by flexible sizing and expert technical assistance. Our team ensures smooth integration into your spray dryer setup, minimizing disruption to your production.Q: How can I determine the appropriate size of heat exchanger for my spray dryer?

A: Selection depends on your spray dryers capacity, required airflow, and process specifications. Our engineering team will guide you through choosing the optimal size to suit your operational needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Heat Exchanger' category

|

THERMAL ENERGY SOLUTIONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |