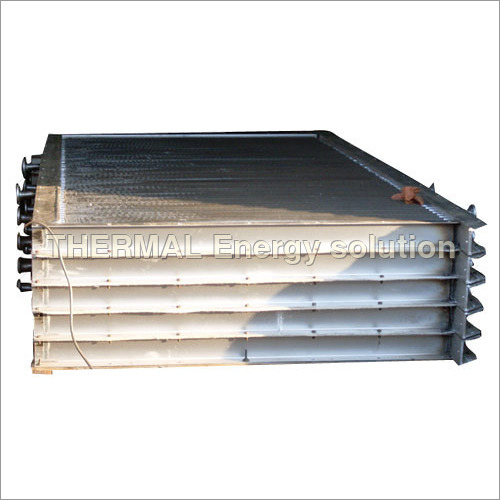

Heat Exchanger for Textile Industry

25000 INR/Unit

Product Details:

- Condition New

- Usage Industrial

- Structure tube Heat Exchanger

- Size Different Sizes Available

- Product Type Heat Exchanger

- Color silver

- Click to view more

X

Heat Exchanger for Textile Industry Price And Quantity

- 25000 INR/Unit

- 1 Unit

Heat Exchanger for Textile Industry Product Specifications

- Industrial

- silver

- New

- Different Sizes Available

- Heat Exchanger

- tube Heat Exchanger

Heat Exchanger for Textile Industry Trade Information

- 1 Unit Per Week

- 1 Days

Product Description

Heat Exchanger for Textile Industry Specifications:

- Type: Air Cooled

- Inlet Temperature: 20 degree centigrade

- Outlet Temperature: 140 degree centigrade

- Primary Exchanger Material: Aluminium

- Tube Material: Aluminium

Superior Thermal Efficiency for Textile Processes

Designed with multiple tube configurations, our heat exchangers maximize heat transfer, supporting processes like dyeing and washing. Their adaptability in size ensures optimal integration within different textile plant layouts, enhancing operational output and energy conservation.

Robust Construction and Customization Options

Manufactured using state-of-the-art methods, these heat exchangers feature a strong metallic structure with a contemporary silver finish. Available in different sizes, we can customize units to fit the exact requirements of textile facilities, ensuring longevity and minimal maintenance.

FAQs of Heat Exchanger for Textile Industry:

Q: How does a tube heat exchanger benefit the textile industry?

A: Tube heat exchangers enhance energy efficiency by transferring heat effectively in textile processes such as dyeing, rinsing, and drying. This reduces energy consumption and operational costs, contributing to more sustainable production.Q: What processes in textile manufacturing utilize these heat exchangers?

A: These heat exchangers are commonly used in processes involving temperature control, including washing, dyeing, bleaching, and drying, where precise thermal management is essential for fabric quality and consistency.Q: When should a textile facility consider upgrading to a new tube heat exchanger?

A: Facilities should consider upgrading when existing equipment shows reduced efficiency, increased maintenance needs, or when production capacity expands, to ensure optimal energy use and improved process reliability.Q: Where can these heat exchangers be installed within a textile plant?

A: They can be integrated into various sections of textile plants, such as water heating systems, effluent treatment setups, and any production area requiring controlled heat exchange for fabric processing.Q: What is the benefit of choosing a new, industrial-grade heat exchanger?

A: A new, industrial-grade heat exchanger ensures enhanced reliability, superior thermal performance, and compliance with industry standards, supporting uninterrupted production and reducing downtime.Q: How do sizing options impact heat exchanger performance in textile applications?

A: Choosing the right size allows for better thermal management tailored to specific process loads, improving efficiency and reducing energy wastage, regardless of plant scale.Q: What distinguishes your company as a heat exchanger supplier in India?

A: With extensive expertise as a manufacturer, exporter, and supplier, we offer tailored solutions, high product quality, and comprehensive support, making us a trusted partner for textile industries across India and internationally.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Heat Exchanger' category

|

THERMAL ENERGY SOLUTIONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |