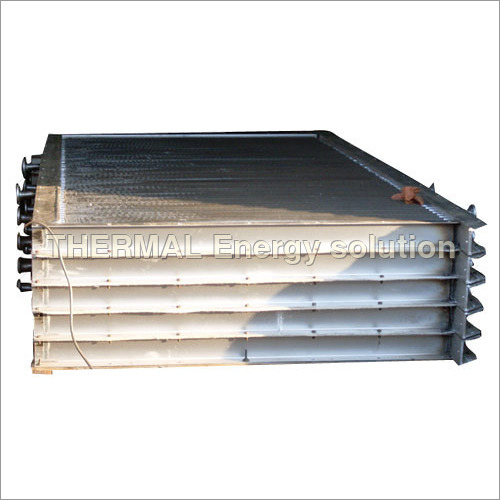

Industry Heat Exchanger

25000 INR/Unit

Product Details:

- Condition New

- Usage Industrial

- Structure tube Heat Exchanger

- Size Different Sizes Available

- Color silver

- Click to view more

X

Industry Heat Exchanger Price And Quantity

- 25000 INR/Unit

- 1 Unit

Industry Heat Exchanger Product Specifications

- silver

- Industrial

- Different Sizes Available

- tube Heat Exchanger

- New

Industry Heat Exchanger Trade Information

- 1 Unit Per Week

- 1 Days

Product Description

Heat Exchanger for Sugar Industry Specifications:

- Medium Used: Air, Water

- Type: Air-Cooled

- Inlet Temperature: 30 degree centigrade

- Outlet Temperature: 130 degree centigrade

Application: Food Process Industry

Versatile Sizing for Broad Applicability

With a variety of sizes available, our heat exchangers can be easily integrated into different industrial systems, ensuring versatility and precise fitting. This adaptability reduces installation complexity and enhances operational flexibility.

Durable Build and Efficient Performance

Constructed with high-quality materials and a resilient silver finish, our tube heat exchangers promise long-lasting performance and corrosion resistance. Advanced design principles optimize heat transfer, making them ideal for intensive industrial operations.

FAQs of Industry Heat Exchanger:

Q: How is a tube heat exchanger typically used in industrial settings?

A: Tube heat exchangers are employed in numerous industrial environments to transfer heat between two fluids efficiently. They are widely utilized in processing plants, chemical industries, and power generation for tasks such as heating, cooling, or condensing fluids.Q: What sizes of industry heat exchangers do you provide?

A: We offer a wide range of sizes to accommodate various industrial requirements. This ensures you can select the optimal size for your specific system or process, enhancing operational efficiency and ease of integration.Q: When should an industry heat exchanger be considered for replacement?

A: Replacement is recommended when there is a noticeable decline in heat transfer efficiency, persistent leaks, or after many years of consistent use. Regular inspection and maintenance can help in determining the right time for replacing your heat exchanger.Q: Where are your heat exchangers manufactured and exported from?

A: All our heat exchangers are manufactured in India, adhering to rigorous quality standards. We export globally, supplying industries with reliable thermal solutions directly from our Indian production facilities.Q: What is the manufacturing process for these tube heat exchangers?

A: Our process involves precision fabrication using high-grade materials, followed by quality assessments and performance testing. Each unit is finished with a silver coating for additional protection and durability before shipment.Q: How does using a tube heat exchanger benefit my industrial operation?

A: Employing a tube heat exchanger improves energy efficiency and system reliability by facilitating precise temperature control. This leads to reduced operational costs and greater process consistency.Q: What maintenance is required to maximize the lifespan of these heat exchangers?

A: Routine inspection for fouling, cleaning tubes, and monitoring for leaks are essential. Regular maintenance helps maintain optimal performance and extends the operational life of your heat exchanger.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Heat Exchanger' category

|

THERMAL ENERGY SOLUTIONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |