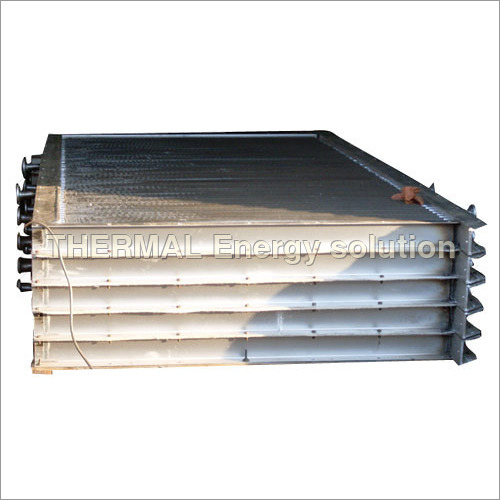

Heat Exchanger For Pellet Drying

25000 INR/Unit

Product Details:

- Condition New

- Usage Industrial

- Structure tube Heat Exchanger

- Size Different Sizes Available

- Product Type Heat Exchanger

- Color silver

- Click to view more

X

Heat Exchanger For Pellet Drying Price And Quantity

- 1 Unit

- 25000 INR/Unit

Heat Exchanger For Pellet Drying Product Specifications

- Heat Exchanger

- New

- tube Heat Exchanger

- Industrial

- Different Sizes Available

- silver

Heat Exchanger For Pellet Drying Trade Information

- 1 Unit Per Week

- 1 Days

Product Description

Heat Exchanger For Pellet Drying manufactured and supplied by us is specially designed for heating systems that are used to remove moisture and watery content from wood and pallets. It is fabricated by using top-grade engineering materials that make it capable to bear harsh industrial conditions. It is provided with a galvanized coating to prevent damages due to rust and corrosion. Buy from us this sturdy product in bulk at a reasonable and low price range.

Heat Exchanger For Pellet DryingSpecifications:

|

Brand |

TES |

|

Medium Used |

Air |

|

Application |

Power Generation, Hydraulic and Industrial Process |

|

Type |

Plate,Air-Cooled |

|

Finishing |

Galvanized |

Top-Quality Pellet Drying Solutions

Engineered for high performance, our tube heat exchanger stands out for its efficiency in pellet drying applications. Crafted in India, it blends durability and adaptability, available in various sizes and a sleek silver finish. Perfect for industries aiming to optimize drying, it ensures maximum throughput with minimal energy consumption. Each unit is produced to meet rigorous standards, providing consistent results even in demanding operational environments.

Adaptable Design, Broad Industrial Usage

Our heat exchangers are developed with flexibility in mind, accommodating the needs of diverse industrial sectors. Their sturdy tube structure and choice of sizes allow integration with existing pellet drying systems. The silver finish not only enhances aesthetics but also resists corrosion. Whether youre upgrading your current operation or establishing a new line, our products from India provide a reliable and scalable drying solution.

FAQs of Heat Exchanger For Pellet Drying:

Q: How does the tube heat exchanger work for pellet drying?

A: The tube heat exchanger operates by transferring thermal energy from a hot fluid to the pellets via tubes, effectively removing moisture as the pellets pass through. This ensures uniform drying and enhances the quality of the final product.Q: What are the main benefits of using a tube heat exchanger in industrial pellet drying?

A: Using a tube heat exchanger increases energy efficiency, ensures consistent drying, and supports large-scale operations. Its robust design minimizes maintenance needs and helps maintain the integrity of the pellets during processing.Q: When should I consider using a new heat exchanger for pellet drying?

A: You should consider a new heat exchanger when upgrading outdated equipment, expanding production, or when consistent and efficient drying is crucial for your industrial process. New units can also reduce energy costs and operational downtimes.Q: Where is this heat exchanger manufactured and supplied from?

A: This heat exchanger is manufactured and supplied by experienced exporters and manufacturers in India, catering to domestic and international industrial markets.Q: What is the typical process for installing the heat exchanger in existing systems?

A: Installation involves selecting the appropriate size, integrating the tube structure with your current drying line, and connecting the necessary fluid inlets and outlets. Our team provides guidance and support throughout this process to ensure seamless setup.Q: How do I choose the right size for my application?

A: Choosing the correct size depends on your production capacity, pellet volume, and drying requirements. Our team assists by assessing your needs and recommending the most suitable size for optimal drying efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Heat Exchanger' category

|

THERMAL ENERGY SOLUTIONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |