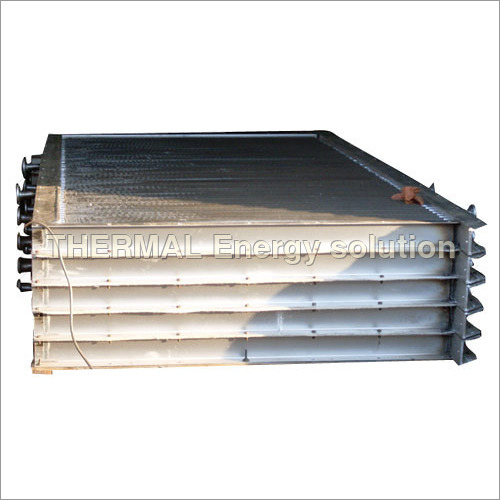

Finned Tube Heat Exchanger

Product Details:

- Condition New

- Usage Industrial

- Structure tube Heat Exchanger

- Size Different Sizes Available

- Voltage 230-415 Volt (v)

- Product Type Finned Tube Heat Exchanger

- Weight 95.21 Kilograms (kg)

- Click to view more

Finned Tube Heat Exchanger Price And Quantity

- 25000 INR/Unit

- 1 Unit

Finned Tube Heat Exchanger Product Specifications

- New

- 95.21 Kilograms (kg)

- Different Sizes Available

- Finned Tube Heat Exchanger

- 230-415 Volt (v)

- tube Heat Exchanger

- Silver

- Industrial

Finned Tube Heat Exchanger Trade Information

- 1 Unit Per Week

- 1 Days

- Australia, Asia, Central America, North America, Western Europe, Middle East, Africa, Eastern Europe, South America

Product Description

Divided into various sub-departments, our company is engaged in manufacturing and exporting Finned Tube Heat Exchanger. Broadly used to transfer heat between two stages, these heat exchangers are widely used in chemical and petrochemical plants. Made up of high-end quality metals, these heat exchangers are highly acknowledged among our clients for their high efficiency, fine finish and unmatched performance. Our product is rigorously checked by panel of expert quality analyzers on different quality standards prior to their final dispatch to the customers.

Features of Finned Tube Heat Exchanger

- Safe transport and easy to install

- Rugged design

- Superior resistance to vibration

Finned Tube Heat Exchanger Specifications:

|

Medium Used |

Water, Air |

|

Application |

Power Generation, Hydraulic and Industrial Process |

|

Material for Construction |

Stainless steel |

|

Finishing |

Galvanized |

|

Brand |

TES |

Optimized Performance for Industrial Needs

Our Finned Tube Heat Exchanger is engineered for maximum energy transfer in demanding industrial environments. The specialized finned tube design enhances heat dissipation, ensuring optimal thermal performance across a range of applications such as chemical processing, power generation, and HVAC systems. Built for reliability, this exchanger performs consistently even under strenuous operating conditions.

Tailored Configurations and Versatility

Available in multiple sizes, the Finned Tube Heat Exchanger can be tailored to fit diverse installation spaces and project requirements. The flexible design accommodates varying voltage specifications (230-415V), allowing integration into existing plant systems with ease. The silver finish reinforces its durability, making it a long-lasting solution for your operational needs.

FAQs of Finned Tube Heat Exchanger:

Q: How does the finned tube heat exchanger improve industrial heat transfer?

A: The finned tube design increases the surface area available for heat exchange, allowing for more efficient thermal transfer between fluids. This makes processes such as heating, cooling, and waste recovery more effective within industrial operations.Q: What sizes and voltage options are available for this heat exchanger?

A: This heat exchanger is offered in various sizes to suit different industrial setups and supports operation at voltages between 230 and 415 volts, making it adaptable for a wide range of electrical systems.Q: When should a finned tube heat exchanger be used in an industrial setting?

A: It is ideal for applications where high-efficiency heat transfer is required, such as cooling systems, power plants, chemical industries, or any processing environment prioritizing energy conservation and effective thermal management.Q: Where is this finned tube heat exchanger manufactured and supplied from?

A: Our company manufactures and exports this heat exchanger from India, distributing to both local and international industrial clients as a trusted supplier.Q: What is the process for installing the finned tube heat exchanger?

A: Installation involves securely mounting the exchanger in the designated area, connecting it to the process pipelines and electrical systems, and ensuring all fittings meet safety and operational standards. Professional assistance is recommended for optimal setup.Q: How should this heat exchanger be maintained for best performance?

A: Regular inspection for scale buildup, corrosion, and fin cleanliness is crucial. Following a routine maintenance schedule will enhance efficiency, prevent malfunctions, and extend the lifespan of the equipment.Q: What are the main benefits of using the finned tube heat exchanger?

A: Key advantages include enhanced heat transfer efficiency, reduced operational costs, and robust construction ensuring long-term reliability in various industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Heat Exchanger' category

|

THERMAL ENERGY SOLUTIONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |