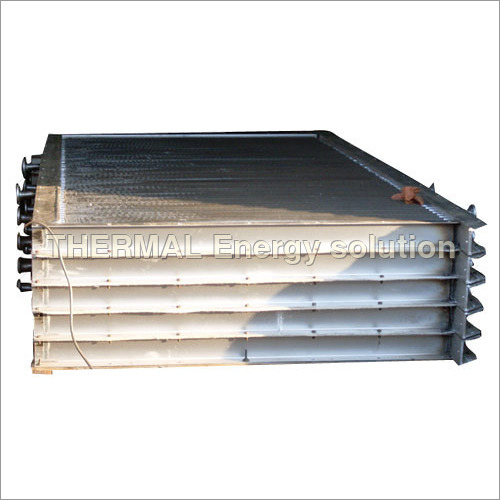

Tea Dryer and Sugar Mill Heat Exchanger

Product Details:

- Usage Industrial

- Condition New

- Structure tube Heat Exchanger

- Size Different Sizes Available

- Product Type Tea Dryer and Sugar Mill Heat Exchanger

- Voltage 230-415 Volt (v)

- Color Silver

- Click to view more

Tea Dryer and Sugar Mill Heat Exchanger Price And Quantity

- 25000 INR/Unit

- 1 Unit

Tea Dryer and Sugar Mill Heat Exchanger Product Specifications

- 230-415 Volt (v)

- Silver

- Industrial

- New

- Different Sizes Available

- tube Heat Exchanger

- Tea Dryer and Sugar Mill Heat Exchanger

Tea Dryer and Sugar Mill Heat Exchanger Trade Information

- 1 Unit Per Week

- 1 Days

- Asia, Eastern Europe, South America, Western Europe, Middle East, Central America, North America, Africa, Australia

Product Description

Following ethical business practices, we are betrothed in manufacturing, exporting and supplying an optimum quality Tea Dryer and Sugar Mill Heat Exchanger.The offered exchanger is best to be used in sugar mills for exchanging heat in effective manner. Under the stern guidance of diligent professionals, provided exchanger is manufactured using top grade raw materials and advanced techniques. Moreover, we offer the provided Tea Dryer and Sugar Mill Heat Exchanger to our esteemed patrons at cost effective rates.

Features:

- Rust proof surface

- High strength

- Longer life

- Excellent finish

Product Detail

|

Minimum Order Quantity |

1 Number |

|

Medium Used |

Air |

|

Application |

Power Generation, Hydraulic and Industrial Process |

|

Type |

Air-Cooled |

|

Brand |

TES |

|

Finishing |

Galvanized |

Precision Engineering for Industrial Applications

Designed to support diverse industrial operations, our tube heat exchanger guarantees efficient thermal exchange, vital for tea drying and sugar milling. Its robust construction and adaptability to different voltages make it an ideal solution for demanding production lines. The availability of multiple sizes ensures seamless integration into your existing systems without compromising performance.

Versatile Sizing for Seamless Integration

Our heat exchangers are available in a range of sizes, allowing for tailored installation in your industrial process. This versatility accommodates space constraints and process demands, making it easy to upgrade or incorporate into both new and existing setups. Each unit is designed for longevity, operational efficiency, and ease of maintenance.

FAQs of Tea Dryer and Sugar Mill Heat Exchanger:

Q: How does the tube heat exchanger benefit tea drying and sugar milling processes?

A: The tube heat exchanger offers superior thermal transfer, maintaining precise temperatures crucial for effective tea drying and efficient sugar milling. This enhances product quality and optimizes processing times, making production more consistent and energy-efficient.Q: What sizes are available for the Tea Dryer and Sugar Mill Heat Exchanger?

A: We offer a range of sizes to cater to diverse industry needs. This enables seamless integration into both new and existing industrial setups, regardless of capacity requirements or physical space limitations.Q: When should I replace or upgrade my heat exchanger system?

A: It is advisable to replace or upgrade your heat exchanger if you experience declining efficiency, frequent maintenance needs, or significant wear and corrosion. Newer models provide improved performance and energy savings.Q: Where can the Tea Dryer and Sugar Mill Heat Exchanger be installed?

A: These heat exchangers are suitable for industrial settings such as tea processing plants and sugar mills. Their adaptable sizing and voltage range allow installation in various production environments across India and internationally.Q: What is the process for installing this heat exchanger?

A: Installation involves placing the heat exchanger within the desired system, connecting input and output lines, securing electrical connections within the 230415 Volt range, and checking for proper integration. Professional installation ensures optimal performance and safety.Q: How do I ensure proper usage of the heat exchanger?

A: Ensure that the unit is operated within its specified voltage range, regularly inspected for any fouling or blockages, and maintained according to recommended service intervals. Proper use extends equipment life and enhances operational consistency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Heat Exchanger' category

|

THERMAL ENERGY SOLUTIONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |