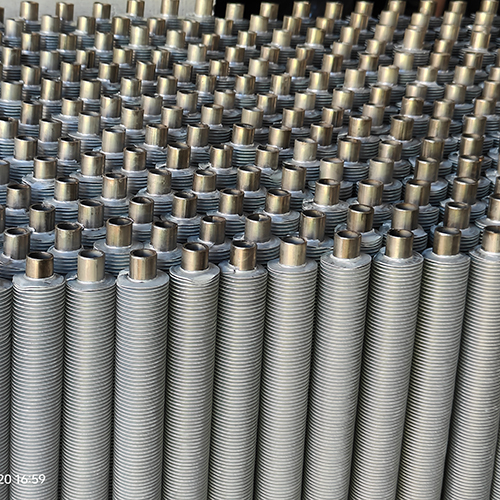

Heat Exchanger Fin Tubes

Product Details:

- Material Alluminium

- Shape Round

- Grade Industrial

- Color Silver

- Warranty Yes

- Click to view more

Heat Exchanger Fin Tubes Price And Quantity

- 300.00 INR/Meter

- 50 Meter

Heat Exchanger Fin Tubes Product Specifications

- Industrial

- Alluminium

- Round

- Silver

- Yes

Heat Exchanger Fin Tubes Trade Information

- 50 Meter Per Week

- 1 Days

Product Description

Heat Exchanger Fin Tubes is a durable and sturdy pipe that is manufactured by using engineering materials with excellent thermal properties that make it capable to ensure efficient transfer of heat and provide high durability due to extreme working conditions. It is available in various sizes with a length of between 3 to 6 millimeters as per customer demands and application areas. The offered product can be delivered to our customers at a price range of 300 to 800 INR per meter.

Heat Exchanger Fin Tubes Specifications:

|

Brand |

Thermal Energy System |

|

Size |

1/4 inch-1 inch |

|

Unit Length |

3m,6m |

|

Material |

Mild Steel,Carbon Steel,Stainless Steel,Galvanized Iron,Aluminium |

|

Type |

Integrally Finned Tubes,G Finned Tubes,L Finned Tubes,External Finned Tubes |

|

Shape |

Circular |

Precision Engineered for Industry

Our fin tubes are designed to meet rigorous demands across industrial sectors. Leveraging premium aluminum material, the round construction offers superior heat transfer and corrosion resistance. The advanced manufacturing process ensures longevity and optimal performance, making them an excellent choice for boiler systems, air conditioners, and other industrial heat exchangers.

Comprehensive Warranty Coverage

Every fin tube is provided with a warranty, underscoring our commitment to quality and customer assurance. This coverage offers peace of mind and guarantees that each product adheres to stringent performance benchmarks. Support is readily available for any concerns during usage or installation.

FAQs of Heat Exchanger Fin Tubes:

Q: How are Heat Exchanger Fin Tubes typically used in industrial applications?

A: These fin tubes are mainly utilized in heat exchanger systems to enhance thermal transfer between fluids. Commonly, they are installed in processes requiring efficient temperature regulation, such as power generation, chemical processing, and HVAC systems.Q: What makes the aluminum material and round shape advantageous for these fin tubes?

A: Aluminum offers excellent heat conductivity and resistance to corrosion, making it suitable for harsh industrial settings. The round shape ensures uniform airflow and efficient heat exchange, resulting in improved operational efficiency.Q: When should I consider replacing or maintaining my Heat Exchanger Fin Tubes?

A: Routine inspection is recommended, especially in high-demand environments. Tubes should be replaced or maintained when there are visible signs of corrosion, reduced thermal performance, or physical damage to maximize efficiency and product lifespan.Q: Where are these Heat Exchanger Fin Tubes manufactured and exported from?

A: These fin tubes are manufactured, supplied, and exported from our facilities in India, ensuring high-quality production standards and reliable global distribution.Q: What is the manufacturing process for your fin tubes?

A: Our fin tubes are produced using advanced techniques that involve precision extrusion and finning of aluminum material. This process ensures tight tolerances, excellent bonding between fins and tubes, and superior thermal conductivity.Q: How does the product warranty benefit customers?

A: The warranty protects customers against defects in materials and workmanship, ensuring long-term reliability and performance. It provides assurance of our commitment to quality and responsive after-sales support.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Finned Tubes' category

|

THERMAL ENERGY SOLUTIONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |